Make Industry 4.0 and Facility Optimization Decisions with confidence. YOUR environment, YOUR Digital Twin. Let’s capture reality.

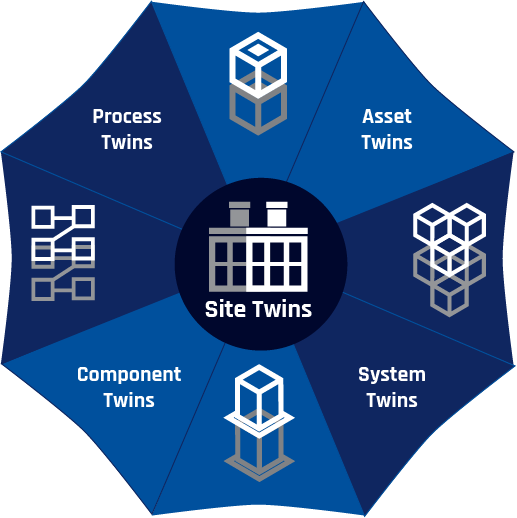

There’s a big push for Industry 4.0 programs for advanced manufacturing, but many organizations don’t have a good place to start. Engineers and Facility Managers are bombarded with information on new Industrial IoT and Smart Factory technologies. Often your digital twin is of a single system, component, process, or asset; figuring out what products to choose and which combination will prove beneficial is at best confusing.

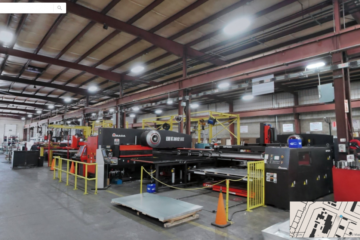

We begin where other digital twins don’t go – your actual facility. It’s where reality meets simulated and big data has a frame of reference all in the context of your physical site. No one should try to design an Industry 4.0 solution without a foundational framework that makes sense of those circumstances surrounding a process, the setting of the problem, or the backdrop for the project.

Bewildered by an overload of options and possible solutions?

These decisions can make or break a career. That’s why we’ve made it our mission to take away the decision-making guesswork.

- Get an integrated visualization framework that removes the mystery

- See how the simplicity of online tools can decode information silos

- Connect with alliance partners to plan projects and avoid roadblocks

DIGITAL TWIN APPLICATIONS

A Digital replica of physical facilities makes it easier to test, prioritize, and share. Work smarter, not harder.

Engineering Projects

Facility Expansion

Line Conversion

Process Optimization

Retrofits & Reshoring

Simulation & Automation

Mistake Free Implementation

Vertical and horizontal IoT integrations, factory automation, agile manufacturing, and simulated process optimizations. The Digital Twin connects the exact location and dimensional data of equipment/infrastructure to ensure project success. Don’t waste time on potential solutions that won't work or don't provide value.

Strategic Planning

IoT Programs

Capital Improvements

Benchmarking

Smart Factory Innovation

Asset Management

No more wasted time.

Optimal asset utilization, operation streamlining, and productivity improvement. It’s important that new technologies lay the groundwork for new business models and we aim to be strategic partners with our clients. Instead of “starting from scratch” each time the factory changes, the Digital Twin shows you where the best opportunities lie.

Communications

Social Distancing

Training

Regulatory/Compliance

Marketing

Remote Operations

Seeing is understanding.

Sales and marketing, stakeholder buy-in, employee relations. For those overseeing facilities, clear communication is critical and is often one of the most difficult tasks of the job. The digital twin unifies operational and environmental data into a single view. Virtually walk through the facility, highlight features, and even show data feeds when in-person visits aren't possible.

HOW WE CAN HELP

If you’re uncertain of where to begin your Industry 4.0/Digital Twin implementations you’re not alone. We get it. We can help.

EXPLORE LATEST WORKS

Case studies

Extending the Digital Twin for Marketing & Sales

View more

Expedited Expansion with Reality Capture Data

View more

Reality Capture & Digital Twin Modeling for Facility Improvement

View more

Nissan Brake Factory Expansion starts with Reality Capture

View more

Reality Capture at Bridgestone Plant for Multi-phase Project

View moreARTICLES & NEWS

Latest posts